वर्णन

इंजेक्शन मोल्डिंग एक होmanufacturingभागमा उत्पादनको लागि प्रक्रियामोल्ड. Plastic Injection Molding is one of the most frequently used manufacturing

processes for creating plastic parts. Thanks to its high-precision,

repeatability, and cost efficiency at scale, plastic injection molding is used for

a variety of products and parts from the smallest insert up to large automotive

& aerospace parts.

The plastic injection molding process requires an injection molding

machine, raw plastic material, and a machined mold. The raw plastic material is

first melted in the injection unit and is then injected into the mold, where it

cools and solidifies into the final plastic part.

इंजेक्शन मोल्डिंग प्रक्रियामा मुख्य चरणहरू:

-क्ल्याम्पि

दुई पक्षको मोल्ड बन्द छ र क्ल्याम्पेड बन्द छ।

-Injection

सामग्री ईन्टोथे मेशीन खुवाइन्छ र मोल्ड तिर धकेलीन्छ। यो भइरहेको बेलामा, सामग्रीहरू ताप र दबाबले पग्लिए। प्लास्टिकलाई त्यसपछि मोल्डमा ईन्जेक्शन गरिन्छ, यस प्रक्रियालाई â € âShotâ called भनिन्छ।

-Cooling

The plastic in

the mold cools and solidifies into the shape of the part.

-Ejection

पार्टकूलहरू पछि यसलाई मोल्डबाट निकालिन्छ।

Auwell offers 2 business models to meet the needs of the client for

plastic injection molding projects. Namely supply tooling only models or, final

products models.

-Tooling Only Models

For this business model,

Auwell offers the tooling design based on the product design and machine data

for client confirmation, the details include tooling structure, lifetime,

tooling material, hardness, etc. Clients may provide completed tooling designs

for production. For this tooling only option, for standard parts, we will use the

most common with globally recognized one for easy maintenance. In general, this

option is preferred for large size and high-volume products, Plastic

Injection Tooling Automotive is a typical catalogue for this business

model.

-Final Products Models

यस व्यवसाय मोडेलका लागि, Auwell प्लास्टिक इंजेक्शन मोल्डिंग भागहरूको लागि जिम्मेवार छ, र ग्राहकको विनिर्देशहरू पूरा गर्न। इंजेक्शन मेशिनको प्रकार र टूलि structure संरचना / डिजाइन प्रयोग गरिएको हाम्रो टोलीद्वारा निर्णय लिइएको छ। यस व्यवसाय मोडेलको लागि, ग्राहकले एक पटक टुलि cost लागत तिर्ने गरेपछि, औवेल टुलि .्ग मर्मत सम्भार र सम्पूर्ण उत्पाद जीवनकालको लागि प्रतिस्थापनको लागि जिम्मेवार हुनेछ। यो मोडल सानो आकार र सटीक प्लास्टिक इंजेक्शन मोल्डिंग भागहरूको लागि उपयुक्त छ। कृपया â € œ मा सन्दर्भ गर्नुहोस्Plastic Injection Partsdetails € अधिक विवरणका लागि सेक्सन।

Another key difference of the two-business model is, for “Tooling Only

Model”, the mold cost is considerable higher than “Final Products Model” as for

“Final Products Model”, Auwell does not make any margin from the tooling

development. For “Final Products Model”, if the clients want to take the mold

or, shift to another supplier, it is not guaranteed that the mold works

properly at another machine at another manufacture, and, a certain proportion

of mold development cost will be charged before mold transferring.

Apart from plastic injection molding, we also provide the following

services:

-Rapid 3D printed prototypes

-ओभरमोल्डिंग

-Insert molding

-थर्मोफॉर्मिंग

-Rubber & Silicone

Molding

प्राविधिक विवरणहरू

-Material

हाम्रो प्लास्टिक इंजेक्शन मोल्डिंग सेवाहरूको लागि निम्न प्लास्टिकमेटेरियल उपलब्ध:

Ø पीए 6/6 | Polyamide 6/6, नायलन 6/6

Ø PARA | Polyaryl एमाइड

Ø PBT | Polybutylene Terephthalate, Valox

Ø PBT-PET | Polybutylene Terephthalate-Polyethylene Terephthalate

Ø PC | Polycarbonate

Ø PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene

Ø PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy

Ø PC-PET | Polycarbonate-Polyethylene Terephthalate

Ø PCT | Polycyclohexylenedimethylene Terephthalate

Ø PE | Polyethylene

Ø PE-PP | Polyethylene-Polypropylene

Ø PE-PS | Polyethylene-Polystyrene

Ø PEBA | Polyether Block Amide

Ø PEEK | पॉलिथर ईथर केटोन

Ø PEI | Polyetherimide, Ultem

Ø PES | पॉलिथर सल्फोन

Ø PET | Polyethylene Terephthalate, Rynite

Ø PLA | Polylactic एसिड

Ø PMMA | पोलीमेथाइल मेटाक्रिलेट, एक्रिलिक

Ø POM | Acetal Polyoxymethylene, Delrin

Ø PP | Polypropylene

Ø पीपीए | पोलीफ्थालामाइड

Ø PPS | Polyphenylene Sulfide, Ryton

Ø PS | Polystyrene

Ø PS-PPE | Polystyrene-Polyphenyl Ethers, Noryl

Ø PSU | Polysulfone, उडेल

Ø पीवीसी | पोलिभनाइल क्लोराइड (किनारा डी)

Ø PVDF | Polyvinylidene Fluoride

Ø SAN | Styrene Acrylonitrile

Ø TPO | थर्मोप्लास्टिक Polyolefin

Ø TPU | Thermoplastic Polyurethane (Shore D)

Ø Custom-sourced Resin

-Moldbase

LKM, HASCO, 1.1730, S50C, S55C, 1050, 1055

-Active Elements

Ø P20, १.२23११, १.२12१२, १.२73738, १.२434343, १.२444444, H11, H13, 20२०

Ø ASSAB: 718, 718S, 718H, S316/S316H/S316 SUP/S316H SUP, POLMAX/168

Ø SAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

Ø DAIDO: NAK80, NAK55, PX88, PX4, PX5, S- स्टार (A)

Ø BOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-मोल्ड सतह

फोटो इच्ने, ईरोडस्ट्रक्चर, शट ब्लास्टर, लाइन पॉलिशिंग, उच्च ग्रस पॉलिशिंग, मिरर पालिशिंग।

-मेशिनहरू: १००--3,००० टोनक्लोजिंग फोर्स

Advantages

-धनी अनुभव

More than 20 years of

experience in plastic injection molding tooling development and part production,

especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to provide fast prototypes in 3

working days, for simple and small size tooling, we are able to deliver first

sample in 4 weeks.

-बृहत समाधान प्रदायक

अउवेलले प्लास्टिक ईन्जेक्शन मोल्डिंग प्रोजेक्टहरूको डिजाइन डिजाइनबाट, प्रोटोटाइप, टुलि। / फिक्स्चर विकास, नमूना, मास प्रोडक्शन, र लजिस्टिक र पोस्ट-बिक्री समर्थनको लागि व्यापक सेवाहरू प्रदान गर्दछ।

-Rigid QC Policies

सब भन्दा कठोर क्वालिटी पॉलिसि सामग्री नियन्त्रणबाट सुरू हुन्छ, र अन्तिममा ढुवानी निरीक्षण सम्म पछ्याइन्छ। सामग्री प्रमाणपत्रमा मिल प्रमाणपत्र, तेस्रो पार्टी रसायनिक घटक, र यांत्रिक सम्पत्ति रिपोर्टहरू, साथ साथै RoHSand पुन: रिपोर्ट समावेश अनुरोधमा समावेश छन्। हामी उत्पादनहरू भन्दा पहिले फ्लो चार्ट्सन्ड कन्ट्रोल प्लानहरू सिर्जना गरेर हाम्रा प्रक्रियाहरू संरचना गर्दछौं, सबै QC प्रक्रियाहरू ISO9001-2015 आवश्यकताहरू र ड्राइंग विनिर्देशहरूको आधारमा छन् भनि सुनिश्चित गर्दै।

-Flexible Payment Term

For tooling, the general

payment term is 50%-40%-10%, meant 50% deposit, 40% after first sample free and

10% 2 weeks after client receive tooling or first batch product delivery. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

अनुप्रयोगहरू

-प्लास्टिक इंजेक्शन मोल्डिंग प्रोडक्ट्स व्यापक रूपमा लगभग सबै औद्योगिक क्षेत्रहरुमा प्रयोग गरीएको छ:

-एयरोस्पेस र रक्षा

-Automotive

-Agriculture Machinery

-उर्जा

-Electronics

-Construction

-Transportation

-Industrial

-उपभोक्ता उत्पादनहरू

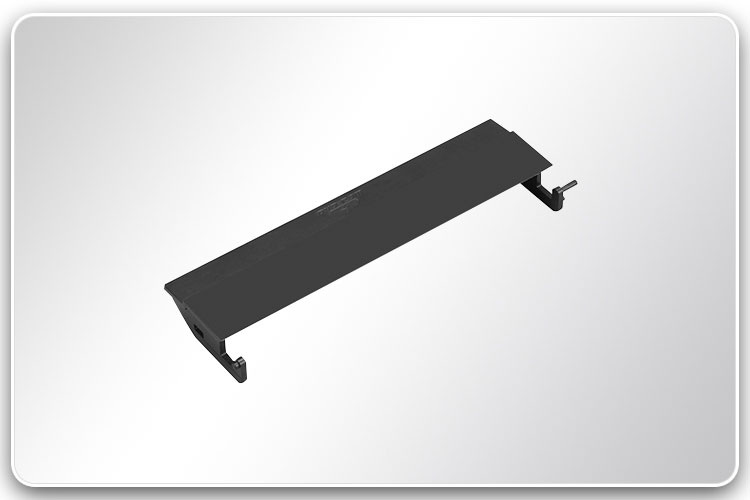

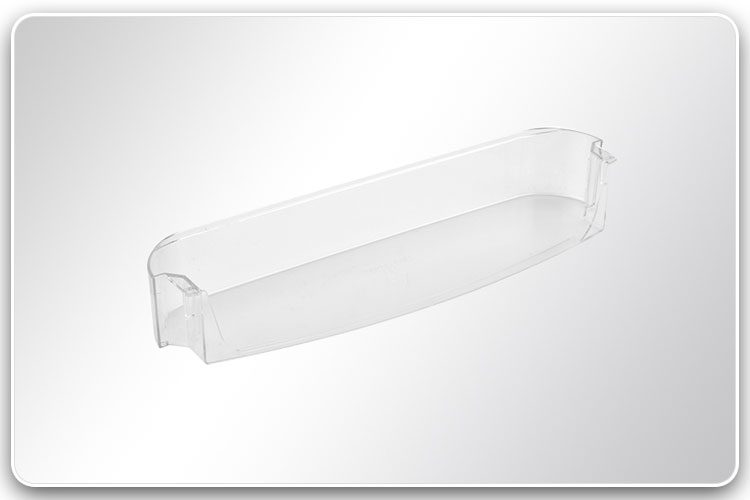

The following catalogues of plastic injection molding products

are the ones which Auwell has produced and supplied to our distinguished

worldwide clients. Please click the relevant pictures for details. Please be

advised, most of the products are for demonstration purpose only.

प्लास्टिक इंजेक्शन मोल्ड मोटर वाहन पार्ट्सको लागि

प्लास्टिक इंजेक्शन मोल्ड मोटर वाहन पार्ट्सको लागि

प्लास्टिक इंजेक्शन पार्ट्स

प्लास्टिक इंजेक्शन पार्ट्स

Plastic Injection ओभरमोल्डिंग

Plastic Injection ओभरमोल्डिंग

Plastic थर्मोफॉर्मिंग Parts

Plastic थर्मोफॉर्मिंग Parts

रबर र सिलिकॉन मोल्डिंग

रबर र सिलिकॉन मोल्डिंग

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик